WOODEN PALLETS AND WOODEN BOX

DESIGN

WINTAM – RELIABLE WOOD PALLETS SUPPLIER

Looking for a reliable supplier of high-quality wooden pallets? Look no further than our company, the premier wooden pallet supplier in the industry!

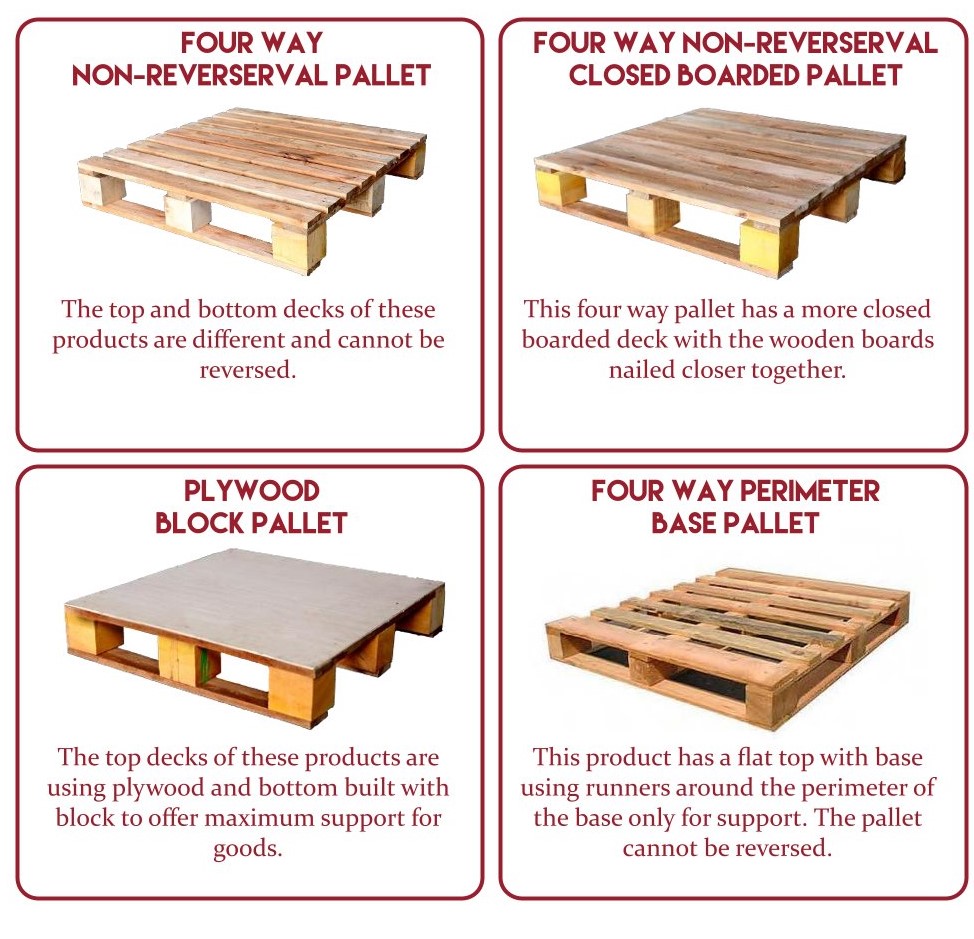

We understand that the needs of your business are unique, and that’s why we offer a wide variety of wooden pallets to meet your specific needs. Whether you require pallets for shipping, storage, or material handling, we have the perfect solution for you.

Our wooden pallets are made from the highest-quality materials, ensuring durability and longevity. We use only sustainable and eco-friendly materials in our manufacturing process, so you can feel good about using our products.

In addition to our standard pallets, we also offer custom pallets to fit your exact specifications. Our team of experienced designers and engineers will work with you to create the perfect pallet for your specific needs. We can even provide logo branding on your pallets to help increase brand awareness.

We pride ourselves on our exceptional customer service and timely delivery. We understand the importance of meeting deadlines and will work with you to ensure that your pallets are delivered on time, every time.

So if you’re in need of high-quality wooden pallets, look no further than our company. Contact us today to learn more about our products and services and to receive a free quote. We look forward to serving you!

QUALITY CONTROL OF WOOD PALLETS

Quality control of wood pallets processing is an essential part of ensuring that the pallets produced are of high quality and meet industry standards. Here are the key steps in quality control for wood pallet processing:

-

Inspection of raw materials: The first step in quality control is to inspect the raw materials used to make the pallets. The wood should be inspected for defects such as knots, cracks, and decay, which can affect the strength and durability of the pallets.

-

Sorting and grading: The wood should be sorted and graded according to its quality and suitability for making pallets. This ensures that only high-quality wood is used in the production process.

-

Design and engineering: The design and engineering of the pallets should be carefully considered to ensure that they meet industry standards and are suitable for the intended application.

-

Manufacturing process: The manufacturing process should be closely monitored to ensure that the pallets are being produced to the correct specifications. This includes monitoring the size, shape, and strength of the pallets, as well as checking for any defects or imperfections.

-

Testing and inspection: The finished pallets should be subjected to testing and inspection to ensure that they meet industry standards for strength, durability, and compatibility with equipment. This can include load testing, stress testing, and other tests to ensure that the pallets are suitable for their intended use.

-

Repair and maintenance: Pallets should be designed for repair and maintenance, and any damaged or defective pallets should be repaired or replaced as needed to ensure that they continue to meet industry standards.

By following these steps, wood pallet processing facilities can ensure that the pallets produced are of high quality and suitable for their intended use. This can help to reduce waste, improve efficiency, and ensure customer satisfaction.